Creating

solutions

together

Revolutionise your processes

Our solutions maximise efficiency, productivity, and capacity, eliminate manual repetitive tasks and improve workplace ergonomics, lower energy consumption, and can quickly be updated as needed to match your future requirements.

From pick and place to assembly and testing, robots and automation can revolutionise the way you set up and run your processes. Whether you have been using robots and automation for years or are considering getting started, we have the experience and expertise to help you make the most of your facility with future-proof automated process optimisation.

Benefits of robots and automation

Endless optimisation options

Robot and automation solutions maximise the speed, accuracy, and efficiency of pick and place, handling, packing, and assembly operations – to name just a few. They eliminate the need for tedious, strenuous, or hazardous manual work, improving workplace ergonomics and safety along with productivity, capacity, and uptime. And they can be designed for any facility and batch size.

System integration

All major robot brands

KSN has extensive experience from robot manufacturers such as:

- Kuka Robots

- ABB

- Universal Robots

Our close cooperation with robot manufacturers and our extensive application experience enables us to select and configure the perfect solution for your application.

THEORY AND PRACTICE

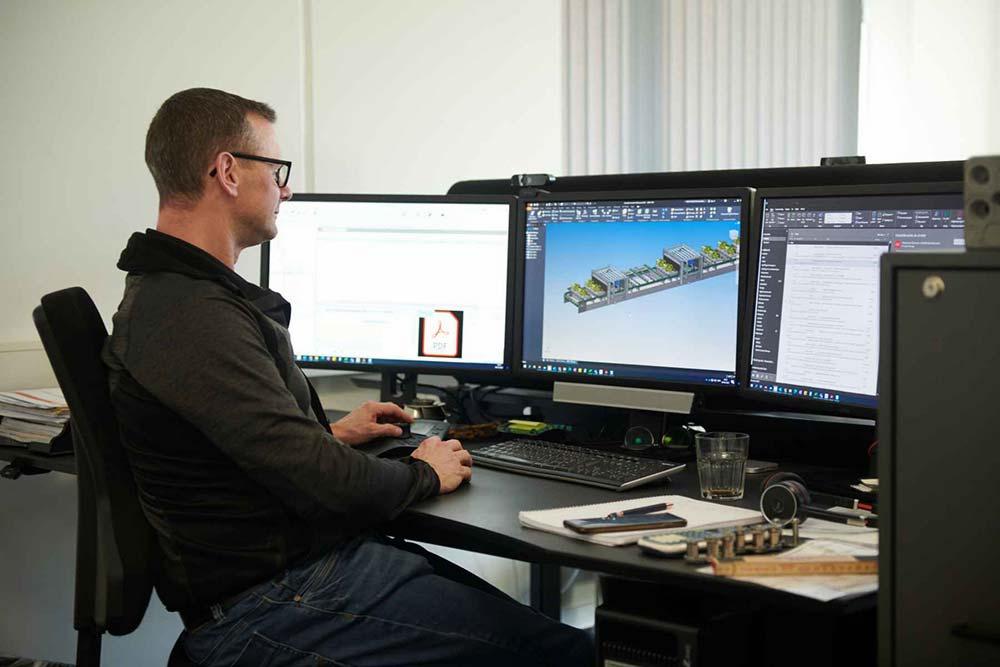

The best of both worlds

The KSN in-house robotics team combines solid theoretical knowledge with extensive hands-on experience, helping you define the solution you need with inspiring new perspectives, innovative ideas, and practical considerations. From analysis and planning to programming, construction, testing, and implementation, KSN has the skills and experience you need.

Operational benefits

6 good reasons for choosing a KSN automation system

A KSN robot or automation system gives you several benefits every day throughout its long service life.

Benefit from our 30+ years of experience

For more than 30 years, we have used our full range of in-house design and construction competences to build and deliver robot and automation solutions that give our customers a competitive edge. When you do business with KSN, you benefit from that experience and our commitment. We listen, we ask the right questions, and we create solutions together with you.

Improved efficiency, productivity, and ergonomics

Our robot and automation solutions improve process efficiency and productivity and enhance workplace ergonomics, increasing capacity and giving you a competitive edge through improved overall facility effectiveness.

Data-based application optimisation

Our solutions can be set up to collect operating data that help you analyse and optimise your robot or automation application, so it runs perfectly and provides the best performance possible.

Low OPEX and TCO

Our robot and automation solutions are designed for robust performance, energy efficiency, and high serviceability, lowering your operation cost. We source high-quality components from leading manufacturers, for example Kuka and UA Robots, to give you high uptime, long service life, fast ROI, and low total cost of ownership from cradle to grave.

1 or 5-year warranty

Get peace of mind with KSN’s product warranty. Our robot and automation solutions come with a 1-year warranty that can be expanded to 5 years with a KSN service agreement.

Future readiness

Our flexible robot and automation solutions can quickly be reconfigured for new applications or batch sizes, preparing you for the future of automated industrial production.

Our process

Building the solution is the easy part

We can design and build robot and automation solutions that do virtually everything. The challenge is to give you exactly what you need. We have defined a process for fulfilling your requirements, from identifying and specifying your demands to designing, engineering, and building a solution that meets those demands – and keeps running for years.

Contact us

Let’s talk it over

Do you need more details about our robot and automation solutions or process?

Contact us today!

Søren Thomsen

Cleaning systems & custom machines

+45 8799 7732

sst( @ )ksn.dk