Creating

solutions

together

More than just a cleaning system

Our solutions are designed for low energy consumption and built using high-quality components. This, combined with high serviceability, ensures that your machines keep running efficiently 24/7/365.

A cleaning system is never just about cleaning. It needs to fit your layout, your workflow, and your cleaning requirements. We find the right solution together with you and support you from initial contact to after-sales. With more than 600 cleaning systems delivered, we have proved our ability to make a difference – for everyone from small local workshops to leading global manufacturers, and in industries ranging from HVAC over industrial components to automotive.

The Basics

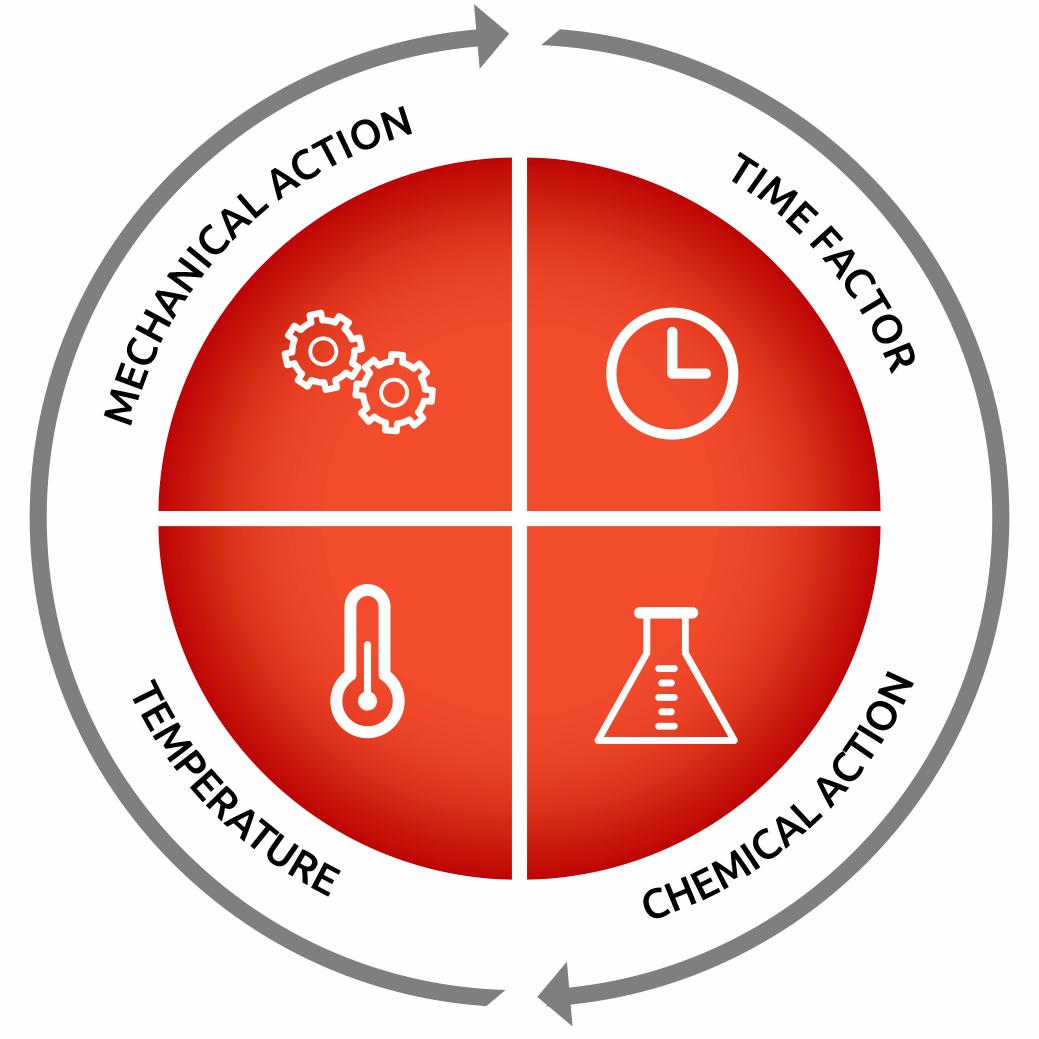

The principles of cleaning

All cleaning processes involve four parameters: temperature, time, chemistry, and mechanics.

Read more about the fundamental principles of cleaning, and how our cleaning solutions are designed to combine the four parameters efficiently.

Industry-leading technologies

Mastering all process stages

We draw on our extensive expertise with industry-leading technologies when designing and building cleaning systems that match your requirements.

Spray cleaning/rinsing

From low to high-pressure spray wash to achieve precision cleaning on surfaces and in holes

Immersion cleaning/rinsing

Wide range of immersion solutions including turbulence and oscillation cleaning

Ultrasound cleaning

Efficient inline and standalone ultrasound cleaning for demanding cleaning requirements

Drying

Energy optimised and highly efficient hot-air drying systems

Vacuum drying

For complex and temperature-sensitive parts

Conveyor systems

Belt conveyors, rotary washing drums, and custom-designed fixture solutions

Filtration

Filters and oil separators for prolonging the lifetime of cleaning and rinsing water

Pick & Place and automation

Automated handling of parts and integration in your production lines

Monitoring and control

PLC-based control systems with HMI touch panels for process overview, energy metering, and remote diagnostics

Standard cleaning systems

Are you looking for a cost-effective standard system? Based on our experience, we have developed a range of standard cleaning systems that give you cost-effective cleaning performance. Check out our range of tried and tested solutions with short lead times.

Customized cleaning systems

We work with you to define your requirements and customize and deliver the cleaning system that matches your needs. KSN customized systems are cleaning solutions for your specific layout, workflow, and cleaning requirements.

Operational benefits

6 good reasons for choosing a KSN cleaning system

A KSN cleaning system gives you several benefits every day throughout its long service life.

Benefit from our 30+ years of experience

For more than 30 years, we have used our full range of in-house design and construction competences to build high-end cleaning systems. When you do business with KSN, you benefit from that experience and our commitment. We listen, we ask the right questions, and we create solutions together with you.

Efficient cleaning

Our cleaning systems are designed and built for efficient removal of all types of contaminants, ensuring high and consistent quality in your processes.

Low OPEX and TCO

Our cleaning systems are designed for robust performance, energy efficiency, and high serviceability, lowering your operation cost. We source high-quality components from leading manufacturers, for example Grundfos pumps and Siemens PLCs, to give you high uptime, long service life, fast ROI, and low total cost of ownership from cradle to grave.

Sustainable operation

Our cleaning systems are designed for low power and water consumption, allowing you to reach your process targets with the lowest possible carbon footprint and environmental impact.

1 or 5-year warranty

Get peace of mind with KSN’s product warranty. Our cleaning systems come with a 1-year warranty that can be expanded to 5 years with a KSN service agreement.

Future readiness

Our cleaning systems are designed and built to facilitate upgrades so you can easily and quickly add filters, oil separators, and communication with other process equipment, adapting your equipment for future challenges and demands.

Our process

Building the machine is the easy part

We can design and build systems that can clean virtually everything. The challenge is to give you exactly what you need. We have defined a process for fulfilling your requirements, from identifying and specifying your demands to designing, engineering, and building a solution that meets those demands.

BUILT TO SAVE ENERGY

Energy efficiency by design

We design all our solutions to use as little water, cleaner, and power as possible. When you order a KSN solution, you can rest assured that you are getting an energy-efficient addition to your facility. It is in our DNA.

Contact us

Let’s talk it over

Do you need more details about our cleaning systems or process? Contact us today!

Carsten Brødsgaard

Cleaning systems

+45 8799 7729

cbc( @ )ksn.dk

Søren Thomsen

Cleaning systems & custom machines

+45 8799 7732

sst( @ )ksn.dk

Michael Jacobsen

Export Sales

+45 8799 7724

muj( @ )ksn.dk